Key Considerations in selecting an antenna for manufacturing environments

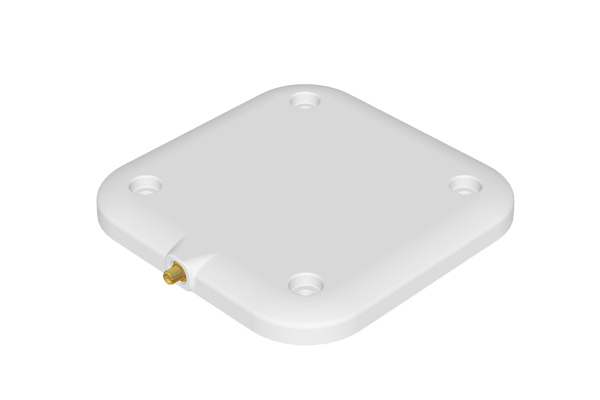

Environmental Rating:

Manufacturing plants are exposed to dust, heat, vibration, and harsh chemicals. Choose antennas with durable enclosures (IP65 or higher) and materials that can withstand industrial conditions without compromising RF performance.

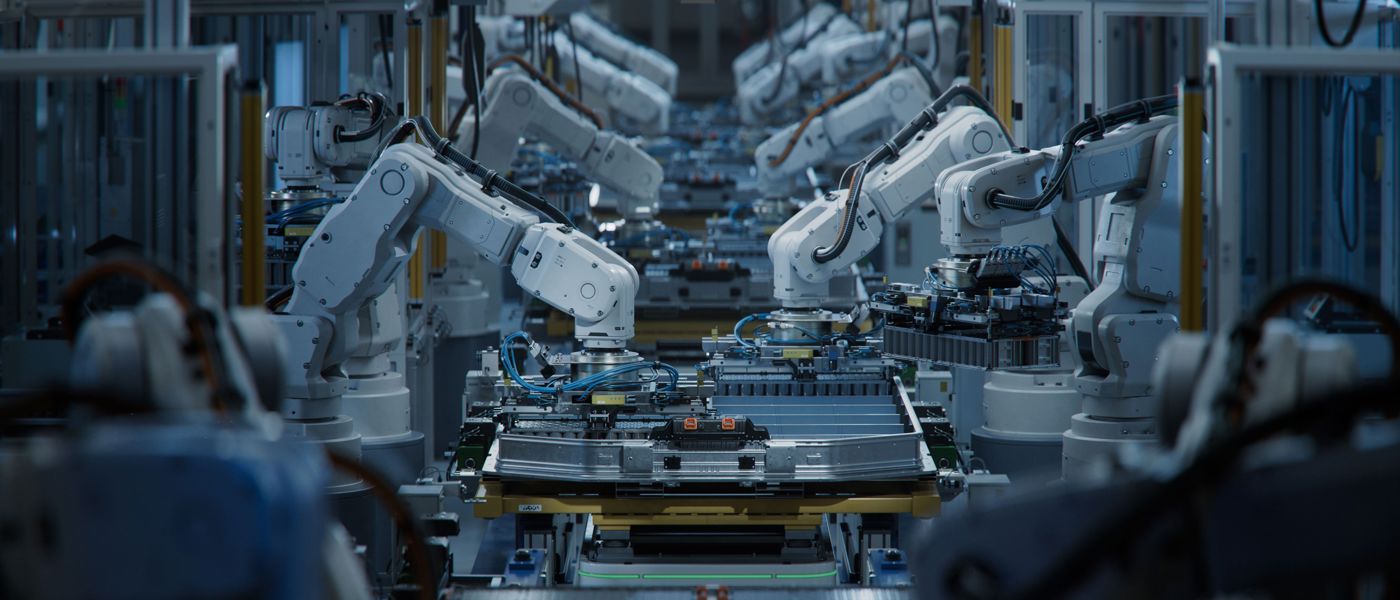

High-Speed Read Capability:

In conveyor-based or automated manufacturing lines, tags may pass quickly or change orientation. For fast-moving tags, consider the antenna coverage and signal strength (beam width and gain) to get a strong read in the limited time.

Tag Orientation:

Consider whether your tag placement and orientation is known or controlled, in which case a linearly polarised antenna would suit. Circularly polarised antennas provide the best performance for dynamic tag movement and orientation variability. Also consider the proximity of the tag to antenna placement. For on-surface reads, near-field antennas are a great fit.

Metal-Heavy Environments:

Machinery, tools, and metallic structures can interfere with RF signals. Use antennas specifically designed for performance near metal or select near-field options for short-range, item-level reads in these conditions.

Mounting Versatility:

Space on production lines is at a premium. Slim, compact antennas with flexible mounting options (e.g., VESA, flush, adhesive) can be easily installed on walls, ceilings, or embedded into equipment.

Use-Case Specificity:

From WIP tracking and tool monitoring to asset management and quality control, antenna selection should align with the required read range, read zone definition, and integration with automation systems.