Read Zone Coverage:

Large entry and exit points, such as loading bays and dock doors, require antennas with high gain and wide beam coverage to read tags moving at speed and across varying orientations.

Durability & Environmental Protection:

Logistics environments often demand rugged, weather-resistant antennas that are able to perform reliably across a range of temperatures, dust, and exposure to outdoor conditions. Look for antennas with an appropriate IP rating (e.g. IP54 for covered indoor, or IP67 and higher for permanent outdoor exposure),

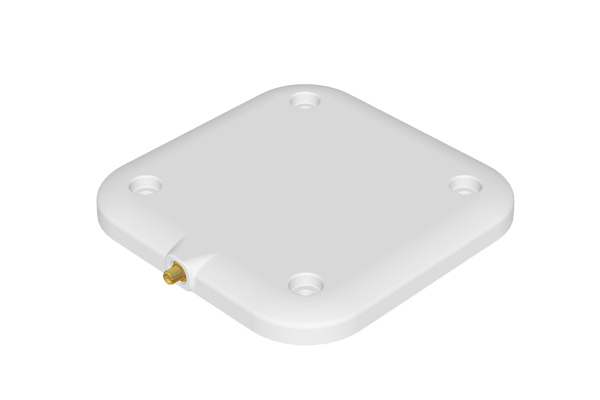

Mounting Flexibility:

Antennas need to be installed on walls, ceilings, doorways, or even embedded in portals, so slim profiles and VESA or flush mounting options can significantly ease installation.

Tag Orientation:

For consistent read rates on fast-moving or randomly oriented tags on parcels, pallets, or crates, circularly polarised antennas are typically recommended.

Application-Specific Requirements:

Each use case, whether for pallet-level shipping, conveyor tracking, cold chain monitoring, or automated gate control, may call for a tailored antenna configuration.